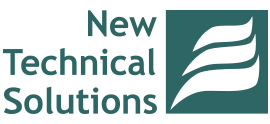

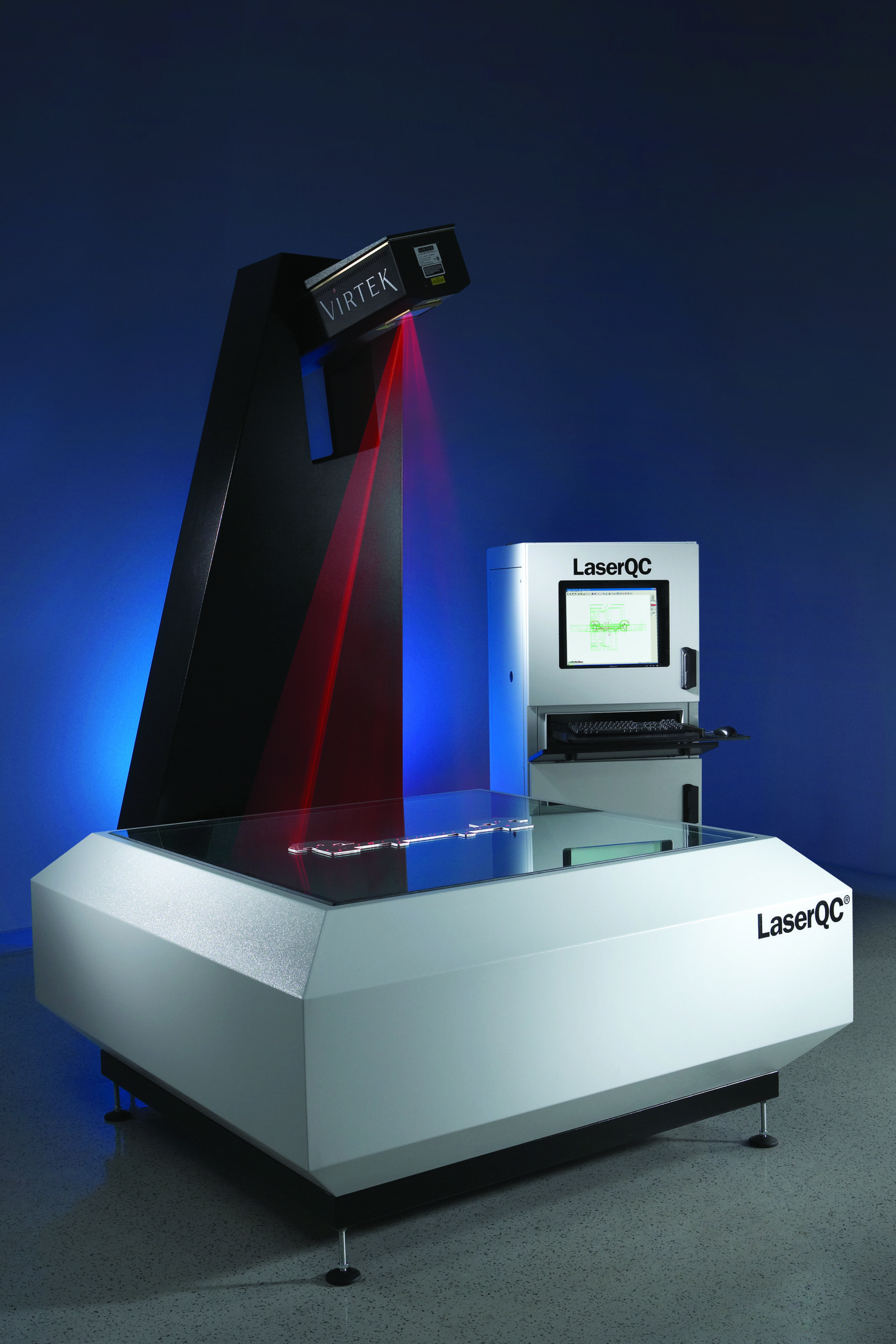

Laser measuring system Virtek LaserQC

LaserQC is the premier self-calibrating laser inspection system in its class. LaserQC dramatically increases throughput in precision sheet metal, tubing, precision foam, leather, aerospace and gasket fabrication. The system is designed for first article inspection, quality reporting (SPC, ISO, LEAN, etc.), reverse engineering and automatic formed measurement.

Laser Fast

LaserQC captures over 500 data points per second to make part inspections laser-fast, right on the shop floor.

Laser Accurate

The system quickly performs 100% inspections accurate to ± 0.002” (0.05mm) for 2D measurements and ± .010” for Formed (3D) measurements.

Shop Floor Friendly

LaserQC offers a reliable, low-maintenance solution that operates along side your facilities CNC equipment. LaserQC self-calibrates and adjusts system settings to accommodate for environmental changes common to the shop floor.

Fast and Easy

LaserQC is designed to set up easily so your system is up and running in less than a day. The intuitive user interface allows new operators to become fully proficient within just a few hours.

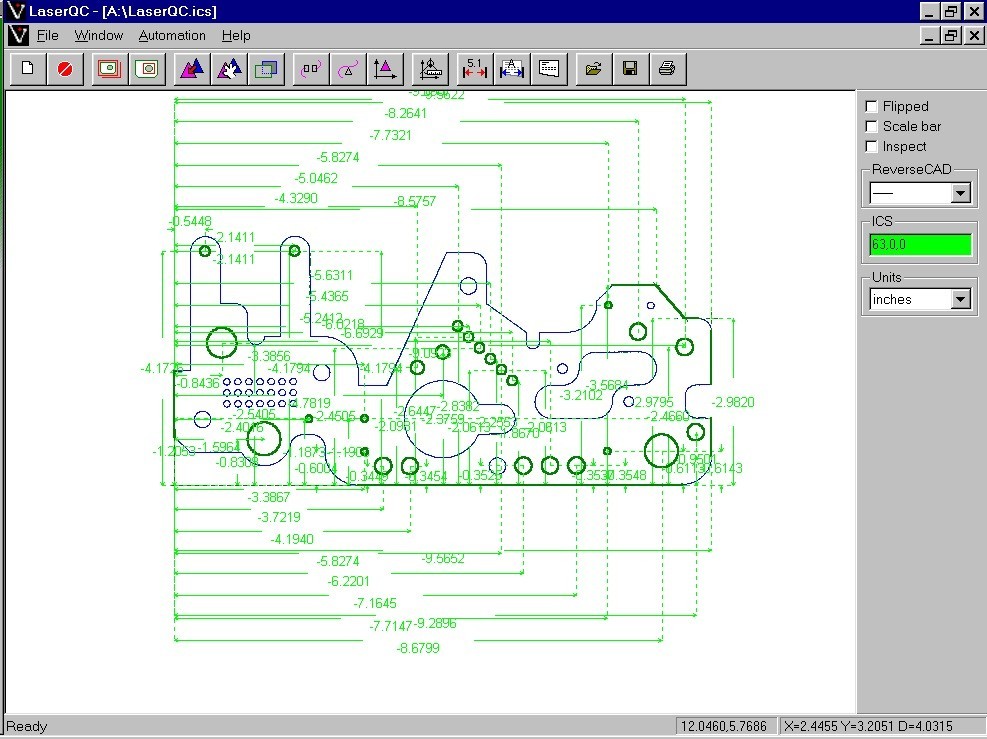

2D Reverse Engineering

2D Reverse Engineering is a built-in feature with every LaserQC system. The scanning process captures the complete profile of existing parts or templates at laser speed and stores the data in CAD-compatible files. The software allows you to manipulate the scan data and part profile on screen to optimize the quality of the CAD model. LaserQC eliminates costly hand measurement and CAD programming. Simply export the LaserQC-generated CAD file for post processing or add it to your CAD library.

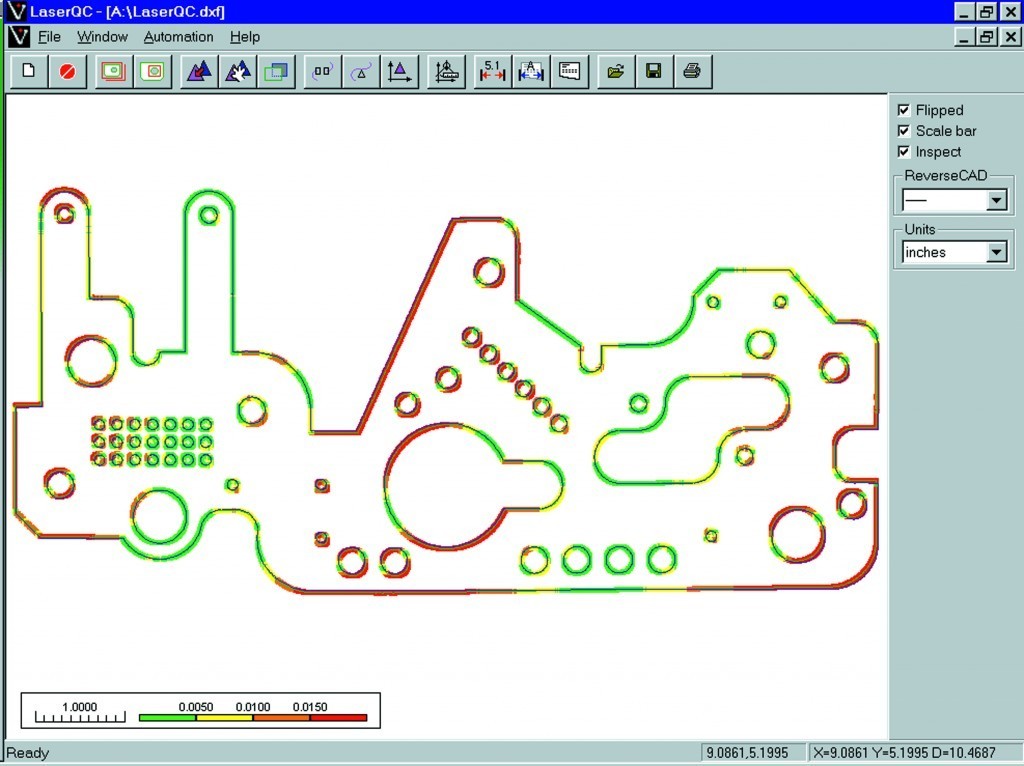

SPC and Quality Reporting

Inspection data from the LaserQC is saved in industry-standard CAD files. From these files, the system generates reports to your exact specifications. The system automatically creates detailed, color-coded inspection records and data files of the scanned part, including CAD data variances. Automatically create documentation and traceability to meet requirements for ISO, TQM, Six Sigma, Lean and QS reporting. Easily export data files into common Windows – based programs.

Description

Scanning Accuracy

±0.05 mm for 2D

±0.25 mm for formed inspection

Maximum Part Thickness

200 mm for 2D,

305 mm for formed inspection

Calibration Automated

Maximum Scan Zone (single scan)

LaserQC? 800 – 760 mm x 760 mm

LaserQC? 1200 – 1220 mm x 1220 mm

LaserQC Expert – 2440 mm x 1220 mm

Oversized Parts Capable with merged scan feature

Overall Dimensions (LxWxH)

LaserQC 800 – 1575 mm x 1220 mm x 2440 mm

LaserQC 1200 – 2007 mm x 1651 mm x 2440 mm

LaserQC Expert – 2870 mm x 2057 mm x 2612 mm

Operating Environment 10 – 38?C (50 – 100?F)

Power Requirements 11OV/60 Hz or 240V/50 Hz

Laser Device & Output Laser diode device with maximum 4.5mW output

Laser Class Class IIIa, meeting the 21CFR 1040 standard

for CDRH certification in North America Class 2M,

meeting the 60825-1:1993+A1:1997+A2:2001,

standard for CE certification in Europe

Software Includes inspection, SPC and reverse engineering

Computer System

Current model PC with monitor,

color printer, keyboard and mouse

Operating System Windows 7

One-year warranty on hardware and software

Extended Warranty Optional

Extended Support Program Optional

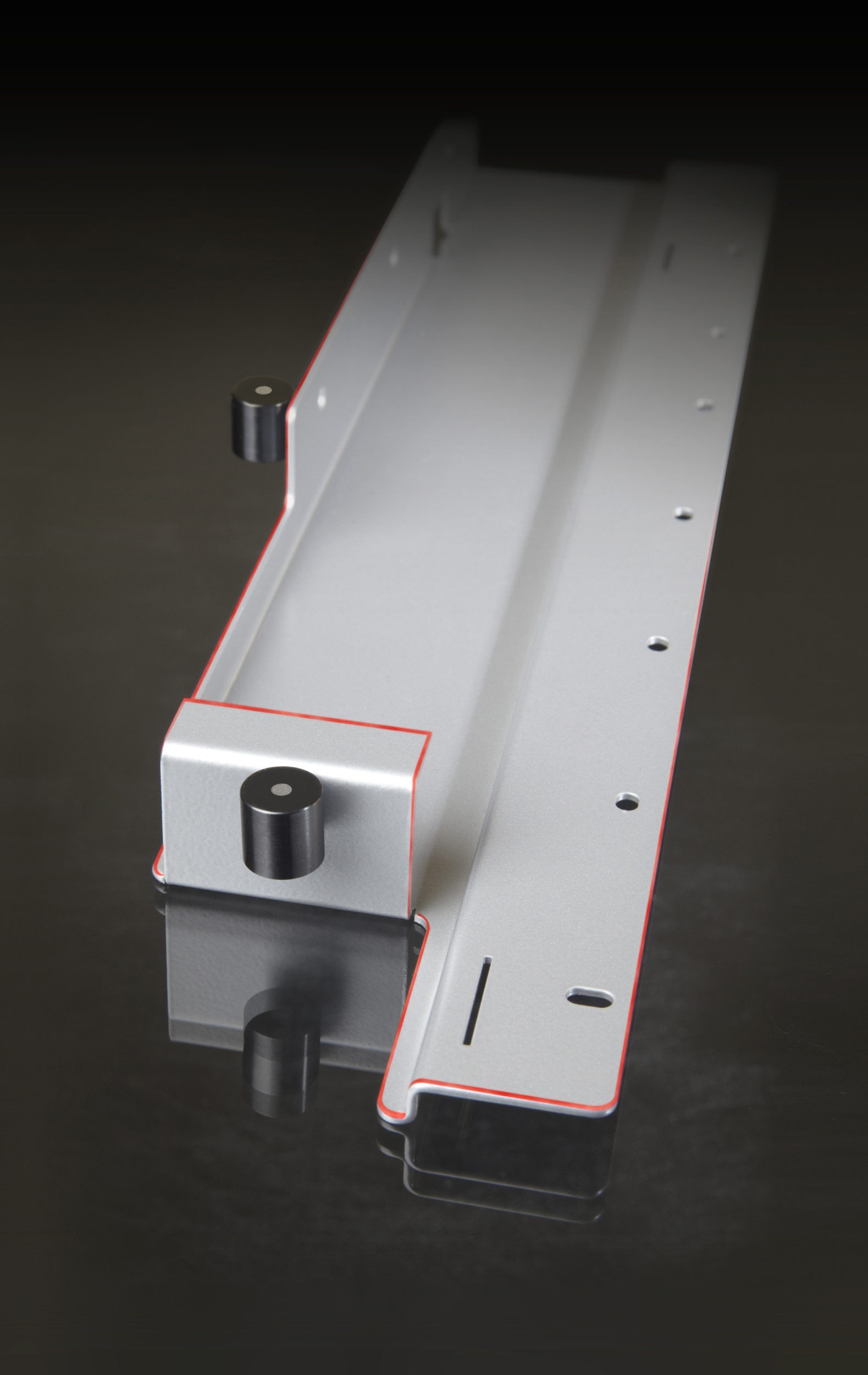

Part Stabilizer Optional