Measuring Systems

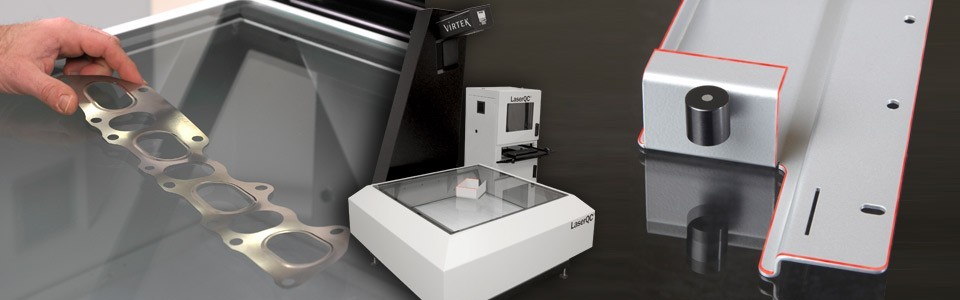

INSPECTION-MEASURING SYSTEM VIRTEK LASERQC FOR DETAILS IN SHEET PROCESSING

The use of manual measuring tools to control the quality of parts in sheet processing is one of the most labor-intensive processes. The LaserQC modern laser measuring and measuring system allows you to carry out any kind of flat parts quickly, accurately and automatically. Designed specifically for the needs of sheet metal manufacturing, the LaserQC reduces sample inspection times to seconds, greatly simplifies the reverse engineering process, improves efficiency, and minimizes errors. The system is able to automatically perform data collection for subsequent evaluation using the statistical process control method (MTP).

SCANNING ACCURACY

Non-contact scanning allows to obtain automatic measurement data with color coding with an accuracy of ± 0.05 mm with two-dimensional scanning, and ± 0.25 mm with automatic measurement of shaped parts (AIF option). This method of measurement eliminates the errors inherent in traditional measuring instruments, resulting in the elimination of repeated processing.

REVERSE DESIGN

LaserQC has a reverse design that allows you to create a drawing based on the available parts from the scan results. The system saves the data in files that are compatible with the CAD drawing.

SYSTEM OF STATISTICAL CONTROL

Scan data is stored in CAD drawings. Based on data from the system, it generates reports, automatically creates detailed color-coded protocols, as well as data files of the scanned part, displaying in color deviations from the CAD drawing.